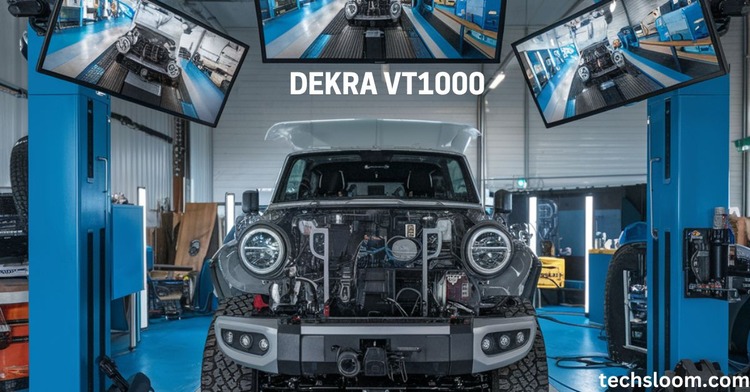

In the world of vehicle maintenance, visual insights can make all the difference. The DEKRA VT1000 brings this concept to life by utilising advanced imaging technology to detect pitting in vehicle components. This innovative system not only identifies hidden issues but also empowers technicians with the information needed to ensure optimal vehicle performance and safety.

Understanding the power of images captured by the DEKRA VT1000 is crucial for anyone involved in vehicle maintenance. By transforming complex data into clear visual representations, this tool enhances diagnostic accuracy and facilitates timely interventions. In a landscape where every detail matters, harnessing the power of imaging is key to preserving the longevity and reliability of vehicles on the road.

Also read this blog: Exploring xannytech.net: A New Era of Digital Innovation

What Are Pitting Images and Why Are They Important?

Pitting images are detailed scans of metal surfaces, showing tiny holes or craters caused by wear or corrosion. These pits weaken parts and can cause major breakdowns if left unchecked.

Pitting detection is essential because it reveals hidden damage that may not be visible to the naked eye. By detecting these imperfections early, mechanics can prevent severe failures and costly repairs, ensuring vehicles remain safe on the road.

Understanding How the DEKRA VT1000 Captures Pitting Images

The DEKRA VT1000 uses advanced imaging technology to capture pitting images of vehicle components. It employs high-resolution cameras and sensors to scan surfaces meticulously. This process produces detailed images that highlight even the smallest pits. The device is designed for ease of use, allowing technicians to quickly assess various parts without extensive training.

Once the images are captured, the DEKRA VT1000’s software analyses them for pitting characteristics. This automation speeds up the inspection process while ensuring accurate results. Technicians can easily interpret the data, making it a reliable tool for vehicle maintenance.

Also read this blog: HU5Z-5K205-F: Benefits, Installation, and Troubleshooting Guide

The Key Features of the DEKRA VT1000 Pitting Detection System

The DEKRA VT1000 boasts several key features that enhance its functionality. First, it provides high-resolution imaging, allowing users to see even minute surface defects. Second, the device offers real-time analysis, enabling immediate feedback during inspections. This feature is particularly beneficial in busy workshop settings.

Another important aspect is its user-friendly interface. The DEKRA VT1000 is designed for technicians of all skill levels, making it accessible for various users. Additionally, it includes automated detection algorithms that identify pitting patterns, streamlining the inspection process further.

The Role of Pitting Images in Ensuring Vehicle Safety

Pitting images play a crucial role in vehicle safety. They help identify structural weaknesses in critical components, such as brakes and suspension systems. By revealing these vulnerabilities, technicians can address issues before they lead to catastrophic failures. Regular inspections using the DEKRA VT1000 help maintain vehicle integrity and prevent accidents.

Moreover, understanding the extent of pitting allows for better maintenance planning. Fleet managers can prioritise repairs based on the severity of the damage, enhancing overall vehicle safety. Thus, pitting images are essential for proactive maintenance strategies.

Also read this blog: Neverwin24: Understanding Its Popularity and Appeal

Common Causes of Pitting in Vehicle Components

Pitting in vehicle components can result from several factors. One common cause is corrosion, often due to exposure to moisture and chemicals. Salt from winter roads can accelerate this process, leading to faster deterioration.

Another cause is friction between moving parts, which wears down surfaces over time. Environmental factors, such as pollutants, can also contribute to pitting. Understanding these causes helps technicians take preventive measures, ensuring vehicles remain in optimal condition.

How Pitting Impacts Vehicle Performance and Durability

Pitting can significantly impact vehicle performance and durability. As pitting progresses, it weakens metal components, leading to mechanical failures. For example, pitting on brake rotors can reduce braking efficiency, posing serious safety risks.

Moreover, pitting affects the longevity of vehicle parts. Components with extensive pitting may require premature replacement, increasing maintenance costs. By addressing pitting early with tools like the DEKRA VT1000, vehicle owners can improve performance and extend the lifespan of their vehicles.

Also read this blog: Exploring Lepbound: Understanding Its Role in Modern Physics

Interpreting Pitting Images: A Step-by-Step Guide

Enhanced Diagnostic Precision: The DEKRA VT1000 provides high-resolution images, enabling precise identification of pitting and other issues in vehicle components.

Real-Time Analysis: This system offers real-time imaging, allowing technicians to diagnose problems as they arise, reducing downtime.

Automated Reporting: The DEKRA VT1000 can generate automated reports, simplifying the inspection process and ensuring consistent documentation.

Predictive Maintenance: By analysing trends in pitting images, the system supports predictive maintenance strategies, helping prevent future failures.

Improved Safety Standards: Enhanced image clarity aids in identifying safety-critical components, contributing to higher safety standards in vehicle maintenance.

User-Friendly Interface: The intuitive design allows technicians to easily navigate the system, making it accessible for users of varying skill levels.

Integration with Other Technologies: Future iterations may integrate with other diagnostic tools, creating a comprehensive vehicle assessment ecosystem.

Cost-Effectiveness: Early detection of pitting can lead to significant cost savings by avoiding extensive repairs and prolonging vehicle life.

Training and Support: As technology evolves, training programs will enhance technicians’ understanding of interpreting pitting images effectively.

Sustainability Initiatives: By promoting efficient maintenance practices, the DEKRA VT1000 supports sustainability efforts in the automotive industry.

How the DEKRA VT1000 Improves Accuracy in Vehicle Inspections

The DEKRA VT1000 enhances accuracy in vehicle inspections by providing detailed imaging and analysis. Its high-resolution capabilities allow technicians to spot even minor surface defects that might go unnoticed with traditional methods.

Additionally, the automated detection features minimise human error, ensuring consistent results. The device’s real-time feedback also means that issues can be addressed immediately, improving the overall reliability of vehicle inspections.

Also read this blog: Unmasking Incestflox: Protecting Kids in the Online Gaming World

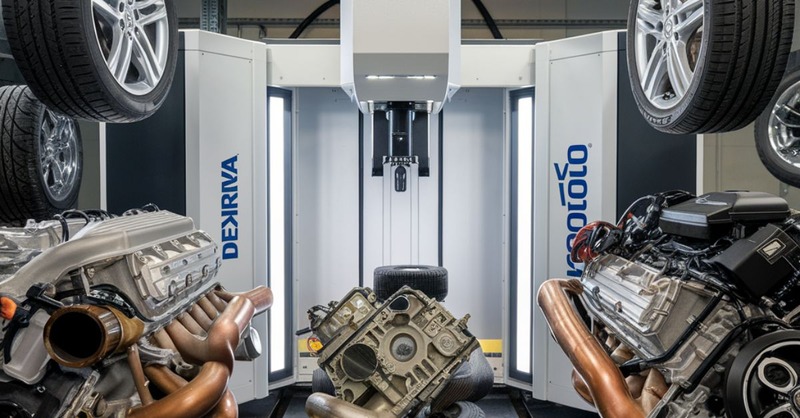

Advanced Technologies Behind the DEKRA VT1000 Pitting Detection

The DEKRA VT1000 is built on advanced imaging and detection technologies. It combines high-resolution cameras with sophisticated algorithms to analyse pitting. This technology ensures that users receive accurate and reliable data during inspections.

Furthermore, the device incorporates machine learning techniques to improve detection accuracy over time. As more data is collected, the system becomes better at identifying and classifying various types of pitting. This advancement makes the DEKRA VT1000 a cutting-edge tool for vehicle maintenance.

Benefits of Using the DEKRA VT1000 for Fleet Maintenance

Using the DEKRA VT1000 for fleet maintenance offers numerous benefits. First, it allows for regular inspections, ensuring that vehicles are always in safe operating condition. Early detection of pitting can prevent costly repairs down the line.

Additionally, the device saves time by streamlining the inspection process. Technicians can complete assessments quickly and efficiently, allowing for more vehicles to be serviced in less time. This efficiency is vital for fleet managers looking to maintain high operational standards.

How to Prevent Pitting in Your Vehicle Components

Preventing pitting requires proactive maintenance strategies. Regular inspections using the DEKRA VT1000 can catch early signs of pitting. Additionally, applying protective coatings to vulnerable components can shield them from corrosion.

Routine cleaning to remove dirt and debris is also essential. Keeping components dry and free from moisture can significantly reduce the risk of pitting. By implementing these preventive measures, vehicle owners can prolong the life of their parts.

The Cost Implications of Pitting Damage in Vehicle Maintenance

Pitting damage can lead to significant cost implications for vehicle maintenance. If not addressed promptly, pitting can result in severe mechanical failures, necessitating expensive repairs or part replacements.

Moreover, the longer pitting goes unnoticed, the greater the risk of secondary damage to surrounding components. This cumulative effect can drive up overall maintenance costs. By utilising the DEKRA VT1000 for early detection, vehicle owners can minimise these financial burdens.

Enhancing Vehicle Longevity with Early Pitting Detection

Early detection of pitting can greatly enhance vehicle longevity. By identifying pitting before it worsens, technicians can implement timely repairs. This proactive approach reduces wear and tear on critical components, leading to longer service life.

Additionally, regular use of the DEKRA VT1000 can ensure that all vehicles in a fleet are maintained to high standards. This consistency not only improves vehicle reliability but also enhances overall safety for drivers and passengers alike.

Comparing the DEKRA VT1000 with Other Pitting Detection Systems

When comparing the DEKRA VT1000 with other pitting detection systems, several factors stand out. The DEKRA VT1000 offers superior imaging resolution, making it easier to spot minor defects.

Additionally, its user-friendly interface and automated detection features give it an edge over competitors. While other systems may lack real-time analysis capabilities, the DEKRA VT1000 ensures immediate results, enhancing overall inspection efficiency.

How to Maintain the DEKRA VT1000 for Optimal Performance

To maintain the DEKRA VT1000 for optimal performance, regular calibration is essential. This ensures that the imaging systems are functioning correctly and providing accurate results.

Routine cleaning of the cameras and sensors is also necessary to prevent dirt buildup that could affect image quality. By following these maintenance practices, users can extend the life of the DEKRA VT1000 and ensure consistent performance.

Also read this blog: Lalo 265123: Unlocking Next-Gen Tech Innovations

Case Studies: Real-World Applications of the DEKRA VT1000

Real-world applications of the DEKRA VT1000 demonstrate its effectiveness in various settings. For instance, a fleet management company reported reduced repair costs after integrating the DEKRA VT1000 into their maintenance routine.

Another case study highlighted a manufacturing facility that used the DEKRA VT1000 to enhance their quality control processes. By identifying pitting early, they improved overall product reliability and reduced defects in their vehicles.

How the DEKRA VT1000 Supports Predictive Maintenance

The DEKRA VT1000 supports predictive maintenance by providing valuable data that helps forecast potential issues. Regular pitting inspections enable technicians to spot trends over time. This information allows for better planning of repairs and part replacements.

By integrating the DEKRA VT1000 into their maintenance schedules, fleet managers can transition from reactive to proactive strategies. This shift enhances operational efficiency and reduces unexpected vehicle failures.

The Future of Pitting Detection Technology: What to Expect

The future of pitting detection technology looks promising. Advancements in imaging technology will likely lead to even higher resolution and more detailed pitting images.

Furthermore, artificial intelligence may play a role in enhancing detection algorithms. As technology evolves, the DEKRA VT1000 and similar devices will become even more essential for maintaining vehicle safety and performance.

Conclusion

The DEKRA VT1000 harnesses the power of images to revolutionise vehicle maintenance and safety. By providing high-resolution pitting images, this advanced system allows technicians to identify issues early, preventing potential failures and costly repairs. Its user-friendly design and automated analysis enhance the efficiency of inspections, making it an essential tool for both fleet managers and individual vehicle owners.

Moreover, the insights gained from pitting images contribute to a proactive maintenance approach. By prioritising early detection, the DEKRA VT1000 ensures vehicles remain reliable and safe, ultimately extending their lifespan and enhancing overall performance on the road.